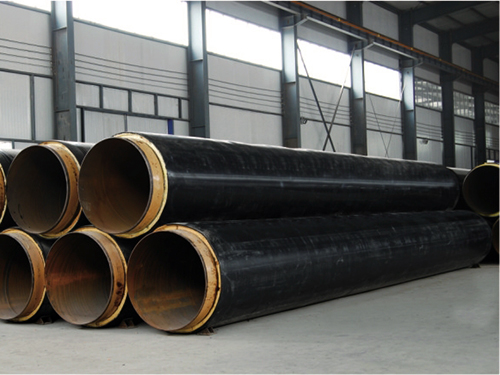

Anti corrosion and insulation pipeline

Description: Anti corrosion (based on actual reports) insulated pipeline is the abbreviation of insulated pipeline. Insulated pipeline is used for the transportation of liquids, gases, and other...

Click: 103

Anti corrosion (based on actual reports) insulated pipeline is the abbreviation of insulated pipeline. Insulated pipeline is used for the transportation of liquids, gases, and other media, and is used for insulation engineering in pipelines such as petroleum, chemical, aerospace, central heating, air conditioning, and municipal engineering

Characteristics of anti-corrosion (based on actual reports) insulated pipelines:

1. Excellent performance ranks first among plastics, 4 times higher than nylon 66 and polytetrafluoroethylene, and 6 times higher than carbon steel.

2. Low friction coefficient, good non adhesion, and self-lubricating properties comparable to polytetrafluoroethylene, with a friction coefficient of only 0.07-0.113. The impact strength of plastic is twice that of PC and five times that of ABC, and it can be maintained at liquid nitrogen temperature (-196 ℃), especially at low temperatures with excellent impact resistance. The impact energy absorption value is high among all plastics, and the noise reduction effect is good.

4. Excellent chemical stability; Except for a few solvents that are corrosive to it, common inorganic, acid, alkali, salt, and solvent materials are not corrosive to this materialDevelopment Status

Anti corrosion (mainly based on actual reports) Insulation pipes are an important factor affecting energy conservation, and the development and application of insulation pipes are increasingly receiving widespread attention from countries around the world.

. After the 1970s, there was widespread emphasis on the production and application of insulation pipes, striving to significantly reduce energy consumption, thereby reducing environmental pollution and greenhouse effect. The insulation industry has a long history, and new insulation materials are constantly emerging. Before 1980, the development of insulation pipes in China was slow, and only a few insulation factories could produce a small amount of underground buried insulation pipes. However, after 30 years of effort, especially after nearly 10 years of rapid development, many products in China's insulation industry have gone from scratch, from single to diversified, from low to high quality, and their applications have become increasingly common. Polyurethane material is currently a commonly used insulation material. Hard polyurethane has many excellent properties and is widely used in Europe and America. About 49% of insulation materials in developed regions such as Europe and America are made of polyurethane, while in China, this proportion is still less than 20%. Therefore, there is still a lot of room for the development of polyurethane insulation pipes in China

Current location:

Current location: