Advantages of flat welding flange connection and stainless steel elbow

Flat welding flange connection is the process of fixing two pipes, fittings, or equipment onto a flange plate. A flange gasket is added between the two flanges, and bolts are used to tighten them together to complete the connection. Some pipe fittings and equipment already come with carbon steel flanges, which also belong to flange connections

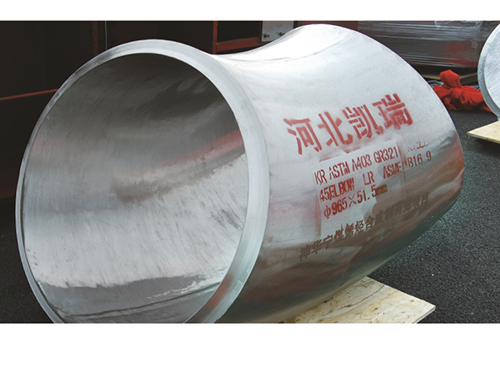

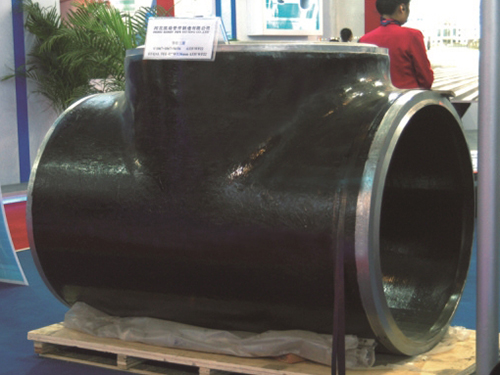

Flat welding flanges are divided into threaded (threaded) flanges and welded flanges. Low pressure small diameter threaded flanges are used, while high pressure and low pressure large diameter flanges use welded flanges. The thickness of the flange plate and the diameter and number of connecting bolts vary for different pressures. In 2000, the annual production was 2.25 million tons, and in 2001, it was 2.46 million tons. In recent years, the growth rate has slowed down. Japan's annual production was 2.43 million tons in 1990, decreased to 1.9 million tons in 1998, and remained unchanged until 2001. And there is no prospect of recovery. India's annual production is 400000 tons, while South Korea's annual production is 700000 tons, both facing the same situation The demand for flat welding flanges is diverse, such as in the automotive, construction machinery, rail vehicles, and shipbuilding industries. The proportion of forgings used in the automotive industry is 67% in Japan, 49% in India, 41% in South Korea, and 40% in China. These proportions will change with the future trends of automotive manufacturing in various countries Stainless steel elbows are fittings that change the direction of pipelines. Elbows are classified by material into cast iron, stainless steel, alloy steel, etc. Stainless steel elbow is a process product made of stainless steel material. When making pipes, stainless steel generally uses two types of stainless steel: 304 and 316. Compared to other materials of pipelines, stainless steel has the following advantages:1. Good performance; And it has good extensibility

2. Easy to form and weld; Unrestricted by water flow rate, larger flow rates can reach 30 meters per second 3. Suitable for various chemical compositions of drinking water; Low maintenance volume, therefore low life cycle cost 4. Multiple connection methods and different types of joints 5. Except for the need for control, no water treatment agent is required and all materials are recycled and reused 6. When piping inside a building with a beautiful appearance, the initial installation cost can be considered

Current location:

Current location: