The manufacturing process flow of carbon steel elbows

The production process of carbon steel elbows:

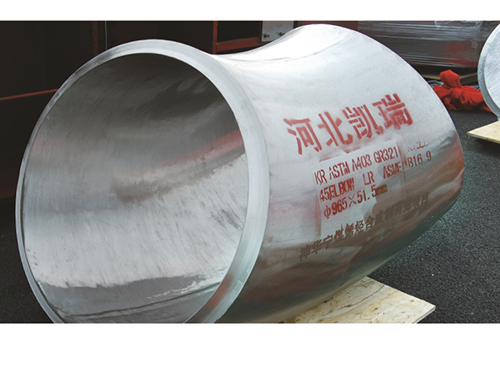

(1) Hot push forming: The hot push forming process of carbon steel elbows uses a one-to-one elbow pushing machine, core mold, and heating device to move the billet on the mold forward under the push of the pushing machine, and is heated, expanded, and bent into shape during the movement. The hot push forming process of elbows has the characteristics of beautiful appearance, uniform wall thickness, and continuous operation, which is suitable for mass production. Therefore, it has become the main forming method of carbon steel and alloy steel elbows, and is also applied in the forming of certain specifications of stainless steel elbows. The deformation characteristics of the hot push bending head are determined based on the law of volume change before and after plastic deformation of the metal material, and the diameter of the pipe blank is determined. The diameter of the billet is smaller than the diameter of the elbow. The deformation process of the billet is controlled by the core mold, allowing the compressed metal at the inner arc to flow and compensate for the thinning of other parts due to diameter expansion. The heating methods used in the forming process include medium frequency or high frequency induction heating (heating coils can be multiple or single coils), flame heating, and reflection furnace heating. The choice of heating method depends on the requirements of the formed product and the energy situation

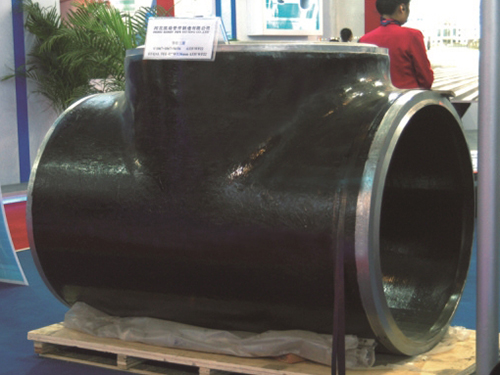

(2) Stamping forming: Stamping forming elbow is an early forming process used for mass production of seamless elbows. It has been replaced by hot extrusion or other forming processes in the production of commonly used specifications of elbows. However, in some specifications of elbows, it is still used when there are special requirements for the product due to the small production quantity, too thick or too thin wall thickness. The stamping forming of elbows uses a pipe blank equal to the outer diameter of the elbow, which is directly pressed into the mold using a press. Compared with hot extrusion process, the appearance quality of stamping forming is not as good as the former; During the forming process of stamped elbows, the outer arc is in a stretched state and there is no excess metal in other parts to compensate. Therefore, the wall thickness at the outer arc is reduced by about 10%. However, due to its suitability for single piece production and low cost, the stamped elbow process is mostly used for the manufacturing of small batch, thick walled elbows. Stamped elbows are divided into two types: cold stamping and hot stamping, which are usually selected based on material properties and equipment capabilities

Current location:

Current location: