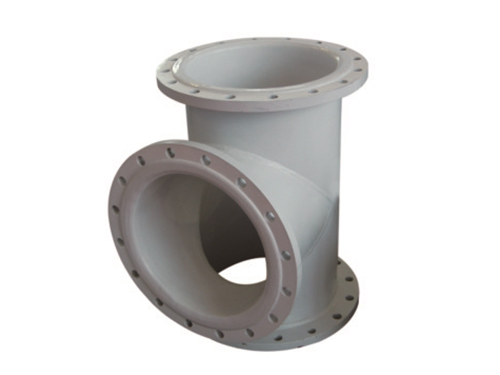

Tee

Description: A three-way fitting is a type of pipe connector used at the point where the main pipeline needs to branch out, and it can be divided into equal and different diameters....

Click: 142

A three-way fitting is a type of pipe connector used at the point where the main pipeline needs to branch out, and it can be divided into equal and different diameters

Tee fittings are widely used in industries such as chemical, civil construction, machinery manufacturing, and shipbuilding due to their convenient and simple use in areas where pipelines have branches Hydraulic bulging of tees is a forming process that uses axial compensation of metal materials to expand branch pipes. The process involves using a one-on-one hydraulic press to inject liquid into a pipe blank with the same diameter as the tee. The two horizontal side cylinders of the hydraulic press synchronously move and squeeze the pipe blank, causing the volume of the pipe blank to decrease. The liquid inside the pipe blank increases in pressure as the volume of the pipe blank decreases. When the pressure required for the expansion of the tee branch pipe is reached, the metal material flows along the inner cavity of the mold and expands out of the branch pipe under the dual action of the liquid pressure in the side cylinder and the pipe blank The hydraulic bulging process for tees can be formed in one go, resulting in high production efficiency; The main pipe and shoulder wall thickness of the tee have increased. Due to the large tonnage of equipment required for the hydraulic bulging process of seamless tees, it is mainly used in the manufacturing of standard wall thickness tees less than DN400 in China. Its suitable forming materials are low carbon steel, low alloy steel, stainless steel with relatively low cold work hardening tendency, including some non-ferrous metal materials such as copper, aluminum, titanium, etc

Current location:

Current location: