The main difference between stainless steel elbows and bent pipes

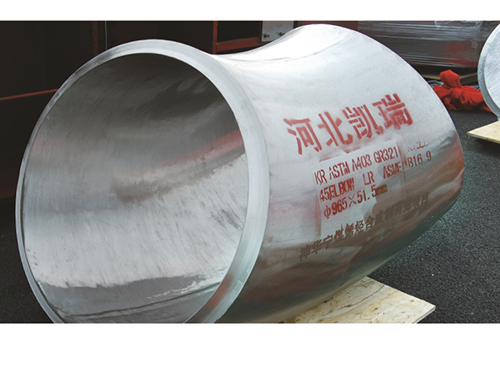

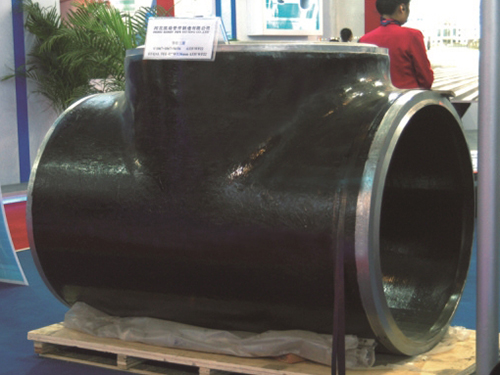

The basic difference between stainless steel elbows and bent pipes is that stainless steel elbows are relatively short compared to bent pipes. A bend is one to two times R, and any larger multiple is called a bend. In terms of production technology, cold bending pipes can be bent using a ready-made straight pipe bending machine, which can be completed in one go without the need for secondary bending. But the elbow needs to be customized by the manufacturer, and the ordering cycle is long. Elbows are more expensive than bends, but their cost-effectiveness is much higher. It is well known that untreated bends are prone to damage, but they are widely used in some less demanding projects due to their low cost

The elbow needs to be customized by the manufacturer, and the ordering cycle is long. Cold bend pipes can be bent using existing straight pipe bending machines. Complete it all at once and don't need to do it twice. There is a petroleum standard for the construction process of cold bending pipes, and an enterprise standard for the West East Gas Pipeline. But in open areas, elbows and bends can be used, considering only the cost. Bends need to be heated, while bends can be cold bent, but the cost of elbows is high. Sometimes bends are used in narrow areas, such as in stone section trenches, because the curvature radius of the bend is small, usually 6D, while the bend is 40D

Current location:

Current location: