What are the differences between butt welded flanges and flat welded flanges

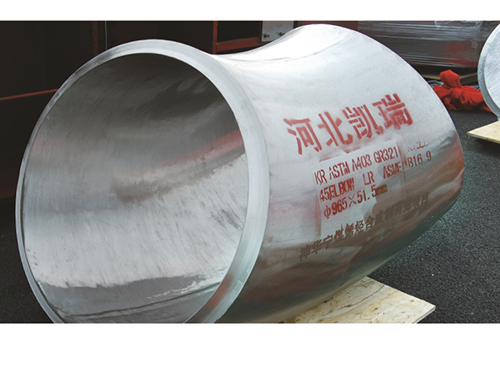

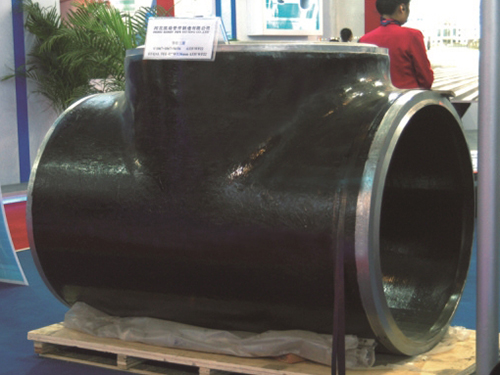

Butt welding flanges are mainly used for butt welding between flanges and pipes. They have a reasonable structure, high strength and stiffness, can withstand high temperature and high pressure, as well as repeated bending and temperature fluctuations, and have good sealing performance. The nominal pressure is 0. 25~2. The 5MPa butt welding flange adopts a concave convex sealing surface. Welding flanges are widely used and promoted in pipe fittings, and they need to be used in corresponding ways and methods

Butt welding flange refers to a flange with a neck and a circular pipe transition, which is connected to the pipe by butt welding 1. The applicable scale of flat welding flanges and butt welding flanges is different, and flat welding flanges are widely used for pressures less than 2. For the connection of 5MPa carbon steel pipes, the sealing surface of the flat welding flange can be considered in three forms: lubrication, height, and tenon groove. Among them, the lubrication type flat welding flange is widely used, mostly in situations where the medium conditions are relatively mild, such as low-pressure circulating water pipelines. Butt welding flanges are suitable for pipelines with high pressure and temperature, as well as high-pressure and low-temperature pipelines. They are also used for transporting pipelines with relatively expensive, flammable, and explosive media. Due to the excellent sealing characteristics of welded flanges, they are not easily deformed and can withstand large pressures, with a pressure range of up to 16MPa 2. The welding methods for flat welding flanges and butt welding flanges are different. Flat welding flanges only require welding on one side between them, without welding the inner opening of the pipeline and flange connection. On the other hand, butt welding flanges require double-sided welding, which reduces the appearance of stress concentration

Current location:

Current location: